Custom Derby Sol Rider wheels, handbuilt in Colorado, with your choice of hubs from Chris King, DT Swiss, Hope, Industry Nine, Onyx, Project 321, Shimano or White Industries.

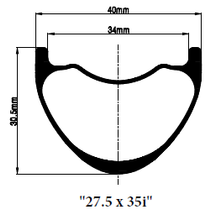

27.5"x35i

Weight +/-10: 465g [AM/Trail/Enduro]

BSD: 584mm

Outer width: 40mm

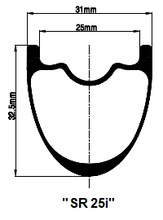

29"x25i

Weight +/-10: 445g [Gravel-Road/XC/AM-Trail]

BSD: 622mm

Outer width: 31mm

Inner width: 25mm

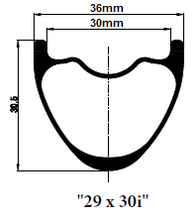

29"x30i

Weight +/-10: 485g [AM/Trail/Enduro]

BSD: 622mm

Outer width: 36mm

Inner width: 30mm

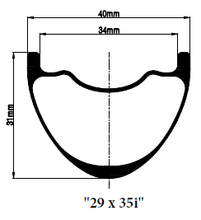

29"x35i

Weight +/-10: 495g [AM/Trail/Enduro]

BSD: 622mm

Outer width: 40mm

Inner width: 34.5mm

Derby Rims original goal to achieve a zero rate of rim damage has been achieved for over 3 years of extensive testing by Derby Rims with a new “Sol Rider” model line, utilizing a proprietary Carbon Fiber Reinforced Polymer (CFRP) hybrid layup of carbon-fiber and plastic fiber composites, Derby Rims calls the “Solstice” layup. Derby Rims has utilized a US designed plastic composite fiber UD combined with 100% carbon fiber UD within a proprietary layup schedule. The Sol Rider (SR) model line rims have tolerated more than three years of extensive Pro and CAT-1 test rider uses, including DH racing, Enduro racing, Free-Ride 35 foot gap jumps, and by dozens of test riders. The new Sol Rider unbreakable line of mountain, and gravel bike rims will be introduced in the most popular 29 x 30i (30mm inside width) and 29 x 35i and 27.5 x 35i sizes for mountain bike trail and enduro uses, and 29/700c x 25i for XC mountain bikes and gravel road bikes, with a 5-year free damage replacement policy for original owners and a lifetime extended replacement warranty including secondary owners.

The first wide profile light weight 465g 27.5 x 35i (35 mm inside tire bead wall width) SR model test rim was “expected to fail very quickly” by the first test rider Austin Fotinas, a recent pro downhill racing champion and free-rider. He proceeded to test while training with downhill race runs and 35 foot gap jumps, which were tolerated for 2 years. Another test rider, Kevin Dwyer, a massive jump free-rider and Cat-1 masters DH racer reported, “these are the smoothest carbon-fiber composite rims I've ever ridden”. For more than 3 years of machine load and dozens of advanced and expert riders testing, there has been zero Sol Rider test rims ever damaged utilizing the Solstice hybrid composite layup.

The smoother ride compared to the same design as the firmer feeling of 100% carbon fiber UD Derby Rims of the same sizes is enabled by the more flexible Solstice hybrid layup use of proprietary plastic UD layers layered between layers of carbon fiber UD. The plastic fiber layers microscopically stretch between alternating layers of carbon fiber in the Solstice layup when flexed excessively by an unintended hard impact or acute weight load to the rim while riding. The increased Sol Rider rim wall flex tolerance prevents “micro-fracturing”, the initial separation of an internal layer's carbon fibers, and further separation of internal layers, which causes rapid rim wall fatigue as the internal composite layers separate apart further, until rim wall collapse showing as a surface crack of a rim, that was caused by acute or excessive flex from folding multiple composite fiber layers.

Rider weight is almost not a factor for durability. Sharp rock hits and suspension bottoming loads focus more than 1000 lbs of acute input causing flex to a rim. Aluminum rims could bend or dent from sharp or heavy hits, but carbon-fiber will flex. And excessive flex and repeated excessive flex damage carbon rims. Usually excessive flex causes internal damage at first, called "micro-fracture", where the actual carbon fibers split microscopically. Additional excessive and normally intended flex will open the internal fracture further, until the internal layers separate enough to become unable to support intended loads, and many months later after the initial excessive hit flex the rim wall collapses showing as a surface crack.